As the whole world faces severe financial crises, “The old-fashioned “I-Style” personnel is no longer able to stand the unprecedented challenges to survive in such a changing world. The only way to stand out is developing into “π-Style” talents,” states Kenichi Ohmae, the world’s leading business and corporate strategist.

In the plastic injection molding industry, a similar but interesting phenomenon comes currently—the standing out of the “π-Style” design teams. Especially those from Taiwanese group companies like ASUS, FOXCONN, GIANT…etc—It is really surprising to find that hundreds of international design awards were received by these teams from famous events like iF, Reddot, IDEA, G-Mark, and the excellence leads them to amazing business opportunities. With a closer look to these teams who successfully drew attentions from giant players, we found that the cross-border integration of design and engineering capabilities played a key strength pushing both of their works and teams to the spotlight.

The term “design” is widely taken as one of the most critical topics for indispensable competitiveness which comes from consumer recognitions on uniqueness, style, identity, preference…etc. From various successful brands, strong consumer recognition also equals higher potentiality in creating higher market share, and of course the profits. That’s why sufficient investigation and study on consumer, fashion and market are always necessary.

However, making the dreamlike concepts into coin trees nowadays has become something much more difficult. Due to the increasingly complicated demands of product innovation, specification, quality, price, manufacturability, and lead time, focusing on the skin-deep concerns like how product looks—the single-leg and out-of-date “I-Style” designs will only make us exhausted in competing with countless designers from the world.

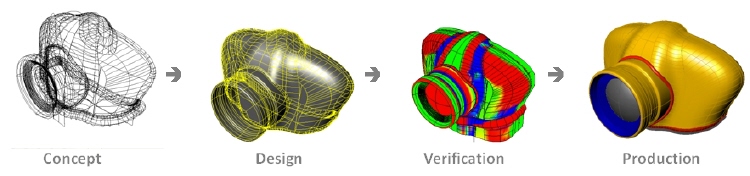

Take consumer products like mobile phones or MP3 players for example, within the first couple of weeks from the day to market, buyers already start keeping their eyes on other newer models. Therefore, besides the design capability, a competitive development team should also seriously pursue the manufacturing effectiveness which means how time and cost arrangements can be optimized during the development cycle from design, iteration, optimization, validation to the final mass production stage. Without this strength, it is almost impossible to survive in the changing market with more and more challenging demands.

This also unveils why “π-Style” design teams become hot. Besides design, most of them have the second core competitiveness on molding simulation technologies, which helps them get outstanding and stable performance for the balance of both legs— originality and manufacturability.

Hence, a reliable, user-oriented and efficient digital prototyping solution is expected for leading the evolution of product development, from the “I-Style” to the “π-Style”. With the advanced 3D kernel which is proved by global users for around one decade, Moldex3D is recognized as the leader in true 3D CAE analysis for injection molding industry. Compared with other solutions that stayed with the over-simplified methods, the accuracy Moldex3D can reach from the runner layout, cavity to the cooling system speaks for the reliability and customer confidence. Besides, no matter for auto 3D meshing or unmatched BLM technology, it greatly minimizes the human effort of the pre-processing jobs and frees you from the whole-day-clicking.

With these user-oriented approaches like unique pre-processing and parallel computing only available in Moldex3D, the design iterations can be tested quickly to assess whether they are over- or under-designing criteria, and users can digitally test a broader range of product performances.

“I-Style” out, “π-Style” in—Moldex3D is just the ideal CAE solution which can connect your aesthetic experience with molding techniques for touchdowns. Interest to know more about Moldex3D solutions? Please feel free to contact our local sales representatives via mail@moldex3d.com