경제상화이 어려운 요즘 어떻게 비용을 절감하고 생산성을 높여 회사의 경쟁력을 향상시키겠습니까 ? True 3D 사출성형 해석 프로그램인 Moldex3D가 여러분에게 최적의 생산조건과 최고의 품질을 가진 제품의 생산에 도움을 드리겠습니다. 제품 및 금형의 설계에서 생산까지 전과정의 비용 및 시간의 절감에 혁신을 이루도록 도움을 드리겠습니다. Aberdeen 그룹이 2006년 10월에 발표한 “시뮬레이션을 통한 설계 혁신 보고서”에 따르면 제품 및 금형의 설계 단계에 시뮬레이션 기술을 접목한 최고 수준의 생산성을 이야기 하고 있습니다. 여러분은 어떻게 하시겠습니까 ?

여러분이 사용하고 계시는 사출 성형 CAE 시스템은 산업 동향을 잘 따라가고 있습니까 ?

Jon Peddie Research, a technically oriented marketing, research, and management consulting firm, stated: “in 2007 the majority of CAD users (63%) are still working in 2D, while 37% work in 3D. However, revenues for 3D CAD surpassed 2D CAD taking 53% of the market.” This report indicates a healthy growth rate through 2012 (15% for the year 2008) for the 3D CAD software industry.

Why can 3D CAD software be so successful? Ved Narayan from The Economic Times wrote, “engineers working in a 3D design environment can eliminate lengthy error checking, make quick design changes, minimize reliance of physical prototyping, accelerate manufacturing cycle and improve support for documentation, publication and marketing processes.”

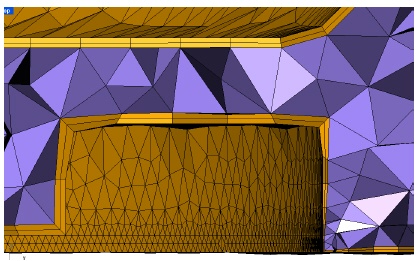

While 3D CAD software allows designers to create objects closer to their imagination, 3D CAE is a particularly advanced technology in that it provides far more precise simulation results for the industrial engineers. Better simulation results during pre-production stage helps to save significantly amount of time on trial and error. Another advantage of using 3D CAE software is that it supports 3D CAD model; while in the past, it requires hours or days (and training) to convert 3D model into shell-like 2.5D mesh before analyzing the data.

2.5D is outdated, but you still stand a chance

One might argue that traditional 2.5D simulation analysis is faster and more efficient. This statement, however, is becoming outdated. First of all, 2.5D analysis can only stay accurate when wall thickness is uniform and thin, which does not response to the diversity of today’s products. 3D analysis technology can overcome this problem by allowing users to perform simulations on thick and solid parts or those that have extreme wall-thickness changes from thin to thick. Secondly, new CPU technologies have delivered incredible breakthroughs in PC performance. The availability of 64-bit computer system, multi-core CPU, PC-Cluster, and etc. can make 3D analysis tasks be processed in no time! Therefore, 3D analysis is becoming the mainstream of CAE software technology, adopting 3D for core analysis is no doubt a “must” in 21st century!

To accelerate, and to stay accurate!

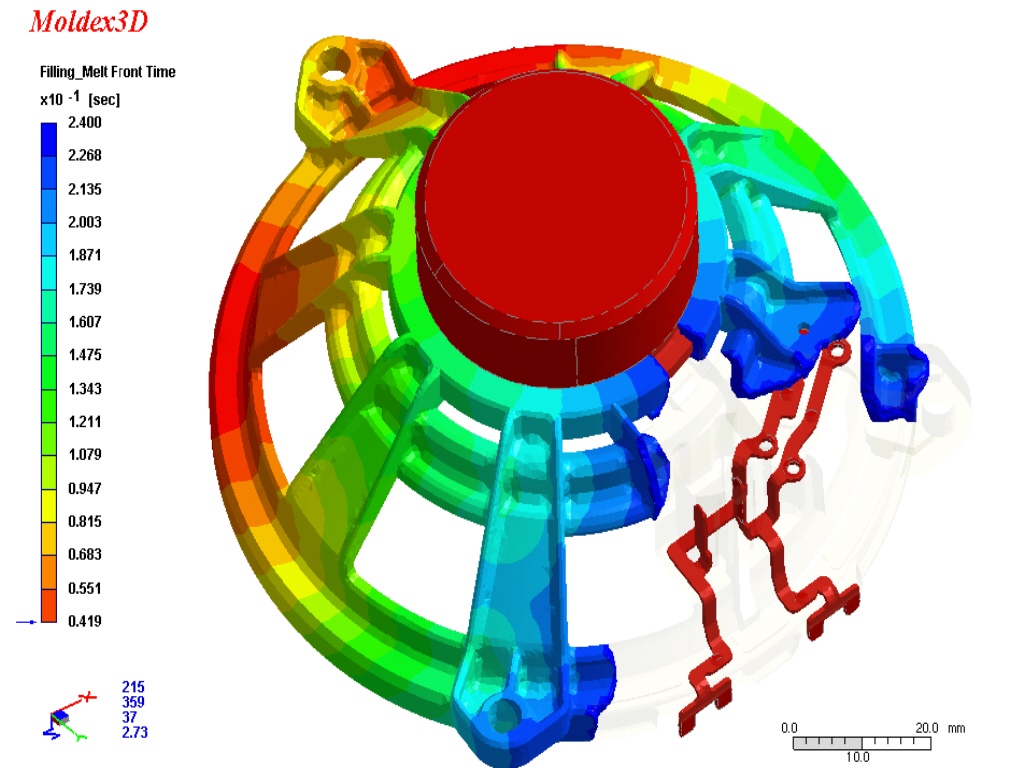

Some of the most important factors to compete during economic recession are to speed up the development cycle, save costs, and increase one’s production capacity. In other words, the time spent on research and development is crucial. Lee Iacocca, an American businessman commonly known for his revival of the Chrysler Corporation in the 1980s, had said: “If you want to make good use of your time, you’ve got to know what’s most important and then give it all you’ve got.” CAE simulation technology can save time by discovering design flaws and critical microscopic phenomena such as fountain flow, runner imbalance, 3D fiber orientation, etc.

To solve problems in advance is to shorten your time to market! For instance, if 95% potential problems of product/mold design can be solved within one day through high-performance CAE tool, the time to market can be reduced to 2 to 3 weeks earlier for mobile phone products that usually require 1 to 3 months to release, the profit margin of manufacturers will be increased dramatically to earn hundreds million dollars!

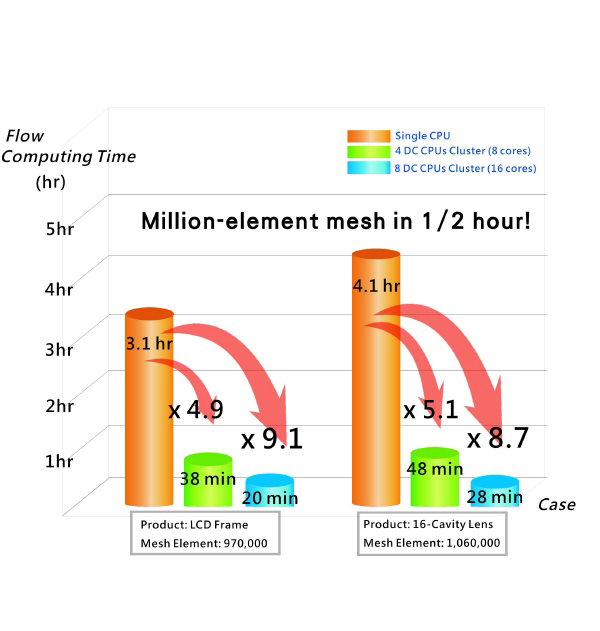

Besides accuracy, “Speed” is another decisive point to help successful manufacturers to use CAE tools to assist them produce faster and better! Moldex3D, the leading true 3D CAE on mold filling analysis, embedded with Parallel Computing technology enhances the computation performance and performs analyses in less time on more complex models that are with large element count. It is the only one to offer the entire parallel computing support in Flow, Pack, Cool, Warp, Fiber, MCM, and so on. Furthermore, Moldex3D Parallel Computing technology supports Multi-CPU, Multi-Core and PC-Cluster platforms. In general, with dual-core CPU power, the computation speed can typically accelerate 50% to 70% faster. Ten times speedup is thus possible using a 16-node PC cluster. Even on highly complex model, such as a 32-cavity model with millions of 3D elements, 3D flow analysis can be easily done within 1 to 2 hours. Now with the newly launched Intel Core i7 processor, the 3D mold filling analyses speed can accelerate beyond your imagination! To optimize your design in one day using True 3D analysis is no longer a dream.

3D Flow Analysis acceleration via Parallel Computing technology

(note: Computing time may vary according to different products)

Time is money!

In order to compete in today’s manufacturing industry; companies’ priorities are no other than to design new products and to shorten time to market. Moldex3D’s leading simulation technology can provide one of the most professional assistances to sharpen your competitive edge, and we never cease to provide our customers the most complete and professional services and supports. Moldex3D will launch the new and enhanced version of R9.1 in January, 2009. This new release includes revolutionary innovations that significantly improve the performance, accuracy, usability, integration and management of analyses. Therefore, it can help users to rapidly solve potential problems of product manufacturability, and to minimize human resource and costs.

Stay tuned for more information to be released: www.moldex3d.com