How can a company strengthen its competitiveness during economic recession? For the plastic molding industry, the answer is very simple: speed up your development cycle, save your cost, and increase your production capacity. The time of CAE analyses on a mold of mobile phone cover is reduced 1 to 3 days, while mobile phone products that once took 6 months to design and build are now being created in 1 to 3 months. The profit margin of manufacturers will be increased dramatically by beating the competition to earn hundreds million dollars!

TIME is money! Now you have the chance to make this happen, try Moldex3D and its high-performance parallel computing technology, and you will be impressed by how it can help you to keep up with the competition.

Now Moldex3D not only provides high accuracy simulation tools, but also takes the lead in parallel computing, which would enhance the computation performance and perform analyses in less time on complex models with large element count. It is the ONLY one to offer the entire parallel computing support in Flow, Pack, Cool, Warp, Fiber, MCM, and so on. Furthermore, Moldex3D parallel computing technology supports Multi-CPU, Multi-Core and PC-Cluster platforms. In general, the computation speed can accelerate up to 50% to 70% faster with dual-core CPU power. Ten times speedup is possible using a 16-node PC cluster. To optimize your design in one day using True 3D analysis is not a dream.

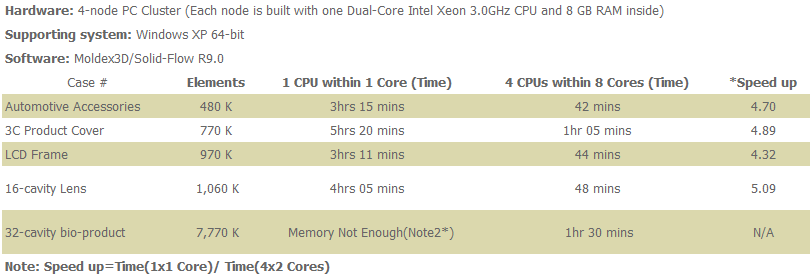

Performance Benchmark

The following table demonstrates the parallel computing performance of Moldex3D/Solid-Flow with various models. The testing platform is a 4-node PC cluster. Each node of this machine is built with one dual-core Intel Xeon 3.0GHz CPU and 8 GB RAM inside. Generally, although speedup partly depends on the geometry, the benchmark results validate that it can have 4 to 5 times acceleration in this cluster platform. Even on high-complex model, such as a 32-cavity model with 7.7M 3D elements, 3D flow analysis can be easily done within 2 hours. Flow analysis is usually the most time-consuming step in all analyses, this improvement implies a big reduction in overall analysis time.

Note1.:Analysis time may be different under different conditions.

Note2 :Current 32-bit CPU can only address up to 4GB RAM. Excluding the memory reserved for Windows itself, an application program can only access up to 3GB memory. Therefore, memory may not be enough for some big scale problems. Although the case is equipped with 8GB RAM, memory can not be applied enough when it is on a single CPU .

Click here to know more about parallel computing!