While visitors arrived at K2010, the biggest international trade fair for plasticsand rubber that takes place once every three years, many visitors were impressed with the show by its scale, quality, technology, and innovation.K2010, held in Dusseldorf on October 27th had ended successfully on November 3rd after a week long rewarding event with experts from every continent sharing their visions, showcasing their ideas, inspiring innovations that shapes thesuccess of the plastics industry.

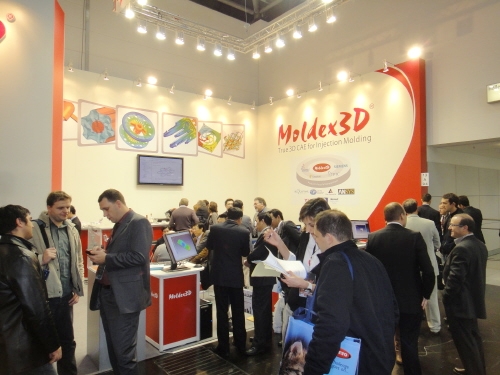

K2010 offered an overview of the latest technical developments, procedures andtechniques, of current construction methods and future trends. More than 700 guests visited Moldex3D booth exchanging information regarding raw material,equipments, and production process condition problems for the plastic andrubber industry. Of those 3,000 copies of Moldex3D brochures and flyersprepared for the visitors, none was left as the number of visitors increased atthe booth!

In order to ensure the service quality, Moldex3D had invited experienced elites from Taiwan headquarter and other countries around the world for multilingual consulting service. Supports from Bulgaria, China, Czech Republic, France, Germany, Holland, Italy, Japan, Poland, Portugal, Scandinavia areas, Slovenia, Spain, Turkey, and United Kingdom determine the success of the event. Moldex3D deeply appreciated your time and the effort.

Inspiring by our world-wide end users successful stories, Moldex3D had prepared live demonstration at the exhibition to unveil the latest achievement of true 3D simulation technologies, Moldex3D R10. It offers new functions and capabilities that enable users to complete evaluation and solve potential design problems more efficiently. This new release includes many new features and customer-driven enhancements.

The official release of Moldex3D R10.0 includes several breakthroughs on developing solver capabilities and improving user friendliness and efficiency, such as enhanced workflow, added support for analysis, remote computing, etc, to help users solve problems more easily and more efficiently. In addition to the new modules added for customers’ needs, Moldex3D has also integrated with more industrial-leading software, including CODE V and NX Nastran, to provide advanced CAE solutions for design verification and optimization.

Moldex3D was overwhelmed by the enthusiasm expressed by CAE specialists and future users who joined us at the K2010. It is our goal to assist part and mold designers to optimize their product design with fast computation and accurate 3D simulation results at every stage of the production. Moldex3D will constantly pursue the best performance of simulation technology. We really appreciate your valuable feedbacks and inspiration! Please don’t hesitate to discuss with your Moldex3D authorized resellers and support staffs near you. We hope to see you again soon!