SolidWorks World 2011 is the annual event held by SolidWorks, and it will bring together 4,000 SolidWorks end-users and resellers. At booth #116, Moldex3D will show its true 3D simulation technology and “eDesignSYNC for SolidWorks”, a SolidWorks-embedded interface that enables users to verify their design more efficiently. We truly look forward to seeing you at SolidWorks World 2011!

SolidWorks World 2011 is the annual event held by SolidWorks, and it will bring together 4,000 SolidWorks end-users and resellers. At booth #116, Moldex3D will show its true 3D simulation technology and “eDesignSYNC for SolidWorks”, a SolidWorks-embedded interface that enables users to verify their design more efficiently. We truly look forward to seeing you at SolidWorks World 2011!

1. What is Moldex3D?

Moldex3D is the world leading CAE product for the plastic injection molding industry. With the best-in-class analysis technology, Moldex3D can help you to in-depth simulate the widest application range of injection molding processes to optimize product design and manufacturability, shorten time-to-market, and maximize product ROI.

Among the Moldex3D product lines, eXplorer is a SolidWorks-embedded product that allows SolidWorks users to perform quick filling analysis for designing better plastic parts; eDesign is suite of tools that helps you to simulate your entire mold design before manufacturing begins; Solid/Shell is a complete series of advanced engineering simulation tools for in-depth analysis and optimization of the most advanced molding processes.

2. Why should SolidWorks World attendees visit Moldex3D booth?

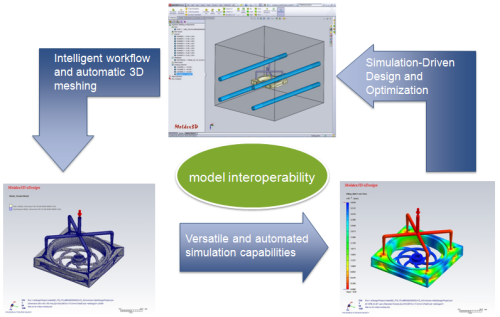

Our latest product, eDesignSYNC for SolidWorks, serves as the bridge allowing SolidWorks users to access Moldex3D/eDesign from within the SolidWorks platform, which provides seamless work flow from design to simulation. Moldex3D/eDesign has been widely adopted as the standard design verification and optimization tool by leading manufacturers globally. It offers complete analysis functions such as filling, packing, cooling, warpage, fiber orientation, insert molding, etc. With the task-oriented and easy-to-use SolidWorks interface, SolidWorks users are able to easily access the professional analysis functions and capabilities of Moldex3D/eDesign, which will improve modeling and simulation interpretability, and encourage design changes for product optimization.

We are also proud to announce a live demonstration of our “Cloud Computing” system. Moldex3D’s private cloud provides a comprehensive solution for users to build their own centralized, high-security, and high-flexibility network for design engineers and plastics specialists that use Moldex3D software. It enables users to quickly submit, schedule, prioritize, and monitor analysis jobs which can be accessed from the local client’s computers to the remote computing network. Completed jobs will automatically download on the clients end. It also helps users to easily adjust computing resources to daily business operations accordingly. Furthermore, this brand-new SAAS-based solution offers businesses a flexible and reliable way to increase the computing power of Moldex3D quickly and efficiently as needed without having to expand into additional investments to achieve the same results.

3. What are the key features of Moldex3D software and how can it help make SolidWorks users’ life easier?

- Reliability – Pioneering 3D technology delivers reliable results

- Efficiency – Parallel computing achieves high-speed calculation

- Capability – Complete analysis modules for design verification and optimization

- Teamwork – Enhance cross-department collaboration

4. How can customers connect with Moldex3D at, before and after the show?

Moldex3D will be at booth #116 in the Partner Pavilion. You can also contact us at:

Website: www.moldex3d.com

Email: mail@moldex3d.com

YouTube: www.youtube.com/user/Moldex3D

We look forward to seeing you at SolidWorks World 2011!